Concrete discharge and loading hoses made of Truckflex® polyurethane

The patented two layer hose with cut-resistant outer layer and wear-resistant inner layer!

So-called concrete hoses are used in ready-mix facilities to transfer material from the concrete mixer to the mobile mixer. Most concrete hoses are made of rubber or, occasionally, PUR and have a seam. The constant high stresses from the rough site conditions mean that the material must be elastic and be resistant to wear, cuts, oils and exposure to UV rays.

When using these products, it is obvious that there is a need for improvement in the following areas:

- The service of the adhesive joint is insufficient, particularly under strong UV

- There are many signs of wear from sharp edges in the area of the mobile mixer´s metal filling hopper. When driving the mixer up to the transfer point, these sharp edges can cut ito the softmaterials.

- Rubber materials are usually sufficiently elastic but sometimes kink if the mobile mixer is not in the centre of the transfer point. If the hose is kinked, it may burst if the seams are not strong enough.

- Conventional concrete hoses do not have a simple solution for preventive maintenance.

When a concrete hose fails in a ready-mix concrete facility, production stops and the defective hose usually has to be replaced immediately. In the worst case deliveries of ordered concrete to the construction site are delayed.

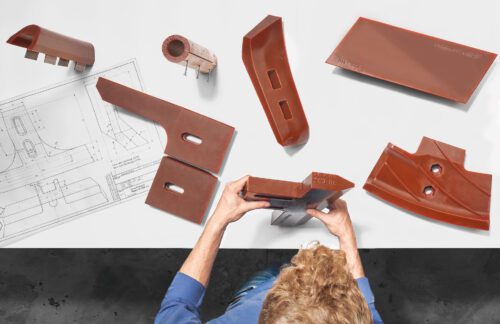

The patented concrete hose made of Hawiflex by Contex does not have seams. It consists of a material system with two distinct, differently coloured layers – the inner layer is soft, the outer layer is hard. Since the two layers have different functions, these innovative concrete hoses last much longer. The harder outer layer provides the soft, wear resistant, inner layer with optimum protection against mechanical damage.

The cutting resistance of the hard outer layer is considerably higher than that of rubber concrete hoses. This has significant advantages. The material is substantially more resistant to cuts and crushing from the mobile mixer´s hopper. Damage from tightening the connection clamp during attachment is also significantly reduced. Since the mechanical properties of the hard outer layer are of higher specification, the overall thickness of the material has been reduced, and accordingly, the weight and amount of material in them has been significantly reduced as well so that the weight of the new sandwich hose is almost 40% less than classical concrete hoses made from PUR. The benefits to the environment and the cost savings and improvement to the ease of attachment are also significant.

New sandwich hose

The new sandwich hose is an interesting variant for preventive maintenance and monitoring the progress of wear in order to minimise the problem of downtimes. The 1.5 mm thick external layer is coloured red and serves as the support for the white, 3.5 mm thick inner layer. Most of the wear comes from the concrete flowing through the hose. This causes material to be worn away from the white, inner coating. If the red outer layer is worn through, it exposes the white, inner layer. It is therefore easy to monitor the situatuion and means that the hose can be replaced well before it fails. The harder outer layer will also hold during ”emergency operations“ for a limited period.

The hose is manufactured without seams or joints, so the problem of failures with the adhesive bonding has been eliminated. The stiff, outer layer also considerably reduces the risk of kinking if the mobile mixer is not manoeuvred to the centre of the transfer point. The kinking properties of the sandwich concrete hose have been significantly reduced by the stiffness of the outer layer. No burst sandwich hoses have been reported so far as far as we are aware. We are confident that this has been archieved by improving the mechanical properties of the outer layer and manufacturing the hose without seams.

The clearance height in the ready-mix concrete facility is constant but the height of mobile mixers varies. This explains the different distances and stresses placed on the concrete hose. When the disctance is only a few centimeters, there is a risk of crushing and an increased danger of extensive material flaking. The new sandwich hose is resistant to this because its outer layer is stronger. The slip properties of the double-layer hose are also good compared with those of rubber.

The classic and repeatedly proven concrete hose – individually adjustable according to your dimensions.

Hawiflex® polyurethane benefits:

- Seamless

- Reduced residual concrete adhesion

- “Lowest inclination to material stopping”

- Resistant against mould oils

- No swelling – no embrittlement

- Signal red for good visibility

- Up to 40 % lower weight in comparison to conventional hoses

- Immensely improved service lives thanks to longer replacement intervals