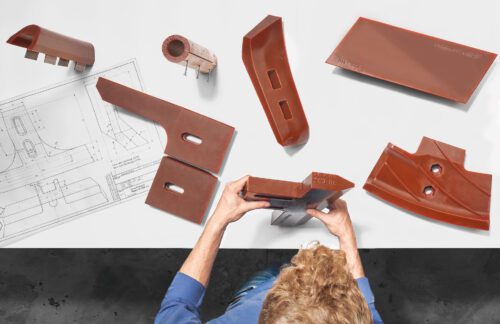

Our material Hawiflex® polyurethane

The manufacture of low-wear polyurethane can rightly be claimed to be an art. We have developed the plastic to such an extent that we can provide it as a finished moulded part in various hardnesses. The properties profile of Hawiflex® polyurethane enables use anywhere where high abrasion is to be expected or dynamic loads lead to extreme stresses.

Our polyurethane-based Hawiflex® plastic extends service life many times over. Special hot-casting processes and an automated production allow us to produce a continuous properties profile.

With nearly 50 years of experience in high-performance elastomers, we can today offer a large variety of special formulations tailored to meet your requirements. This is achieved by special measures, such as the specific introduction of additives into our formulations of the initial raw materials. Our permanently further developed “intelligent materials construction kit system” offers designers and engineers solutions for small and medium-sized production runs in mechanical engineering.

Physical properties

The physical properties of Hawiflex® polyurethane systems have been created for use under the most extreme conditions: High abrasion resistance with excellent tensile strength combined with maximum dynamic loading requirements. Our polyurethane-based Hawiflex® plastic extends service life many times over.

Temperature range

The properties of Hawiflex® polyurethane are naturally temperature-dependent. For dynamic loading, the temperature limit for our standard systems is approx. +80°C to ensure no material breaks and cracking. Brief peak loadings up to +120°C are possible and permitted. But our company also offers special formulations for permanent loads above +80°C. As the temperature decreases Hawiflex® polyurethane becomes less elastic, but applications up to -40°C are easily possible without the materials becoming brittle.

Chemical properties

Hawiflex® polyurethane offers an excellent resistance against oil and grease, petrol and different solvents. Hawiflex® polyurethane is not changed by weather effects such as sunlight, oxygen and ozone. We even offer standard products resistant to considerable hydrolytic and microbial attacks.

Acoustic properties

The sound-absorbing properties of Hawiflex® polyurethane are particularly apparent where bulk material is transported. Your staff will be delighted that noise levels are reduced by up to 50 %.

Hawiflex® polyurethane advantages for moulded parts or coatings:

- Resistant against cuts

- Resistant against wear and tear

- Resistant against oil

- Easy to clean

- Gentle on coatings

- Gentle on bulk material

- Reducing noise levels by up to 50 %

- Energy saving

- Extending service life

Hawiflex® offers a considerable range of levels of hardness:

| Shore-class | min | max |

| Shore A | 35 | 95 |

| Shore D | 58 | 80 |

Fields of application for Hawiflex® polyurethane

The PU technology for wear protection and corrosion protection

The original Hawiflex brand has been an integral part of wear protection for over 60 years. Wear-reducing polyurethane technologies for moulded parts and coatings, which are used in particular in applications with a long service life and enormous wear resistance, have been established as a result.

Hawiflex® polyurethane convinces due to its excellent resistance against abrasion and wear, oil and chemicals and has consequently proven itself time and time again. Competitors have often tried to emulate the brand but the company managed to further extend its technological advantage and to continuously secure its position as the market leader. Today, Hawiflex® polyurethane products by Contex are successfully used by many industries and in nearly every industrial application and offer a clear cost structure as well as a considerable advantage.

And to ensure that you always have an advantage, we have at all times provided our planning and production from the same production site in Witten. We can thus guaranty that all our products are “Made in Germany”. Also those individually developed together with our clients.

Hawiflex® polyurethane products in use:

- Agricultural engineering

- Automotive industry

- Bulk materials industry

- Concrete and mixing technology

- Construction industry

- Materials handling

- Mechanical engineering

- Plant construction

- Plastics production

- Printing and paper industry

- Recycling

- Shipbuilding and marine industry

- Textile industry

- Timber industry

PU-Kunststoffe aus dem Labor:

Today’s ideas, tomorrow’s products

It is a science in itself to produce the perfect mix of different components, processing systems and special additives for a component that is as hard-wearing as it is low-wear – we have been doing nothing else with Hawiflex® for over 50 years.

Experience that pays off for you.

We owe our significant market position not least to ongoing research into new, even more suitable polyurethane-based materials and the further development of our existing product portfolio. In combination with in-depth knowledge of all current and future process requirements, this interaction guarantees both product innovations and customised solutions for your applications. It goes without saying that we fulfil the legal requirements.

We take a very close look.

Using the latest measurement and analysis technology, we examine the interaction of all components and parameters in detail under laboratory conditions and, of course, in practical operation. This informative measurement data and all feedback from our customers are incorporated into the new or further development of our products and form the basis for their exceptional quality.

A service you will appreciate.

In our technical centre, we not only test all our products, but can also simulate a large number of customer applications very well. This enables us to ensure that our products are optimised precisely to our customers’ requirements.

Plastics from the laboratory: today’s ideas for tomorrow’s products

The time available to us as developers from the idea to the solution requires valid statements in the individual development steps to ensure tomorrow’s success. Our extensive test laboratory ensures this. Today’s materials have to fulfil fast-moving requirements in the best possible way. It is particularly important to us that we do not transfer the field of experimentation to you, but complete meaningful tests at our premises. Our laboratory is equipped with the necessary static and dynamic testing methods. We focus our considerations on the service life of the components.

Play it safe and continue to purchase the usual top quality Made in Germany from us. Our contact partners will be happy to advise you.