Hawiflex® polyurethane in the glass industry

proof for glass – without metal residue

Optimised abrasion protection for all glass manufacturing processes. Abrasion-resistant. Free of metal residues.

The processing of glass as a raw material leads to heavy wear on plant and machinery. The processing of the raw materials required for glass products leads to heavy wear on plant and components. Hawiflex® PU coatings enable innovative preventive and sustainable wear protection.

Find out more about the customised application options for your company.

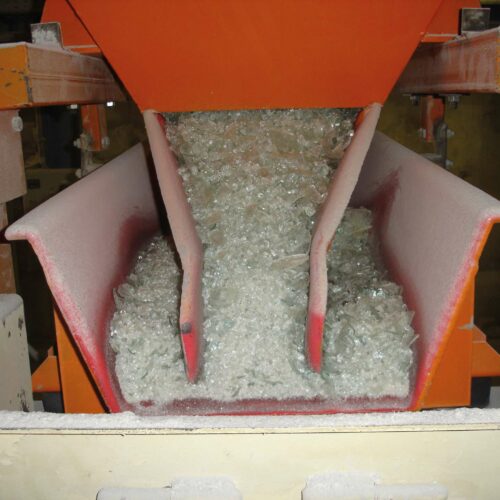

The challenge

Heavy wear in glass production has always been one of the biggest challenges in the glass industry. Added to this is the high demand for purity of the valuable raw material. In order to manufacture perfectly pure products, abrasion residues must be avoided in the production chain. Some system components must also be able to withstand the increased abrasion properties of glass cullet. Transport and further processing place correspondingly high demands. Heavy abrasion and service life problems are the result.

The innovative solution

With its high-quality Hawiflex® PU coatings, Contex relies on an innovative solution that utilises the optimum properties of polyurethane plastic. This is achieved primarily through particularly good abrasion and cut resistance. Whether sharp-edged glass cullet or fine quartz sand – coated with Hawiflex® polyurethane, cullet trolleys, hoppers and conveyor belts withstand erosive material influences many times longer. This reduces downtime and optimises production costs. We solve service life problems in the glass industry with an innovative solution – high-quality PU coatings with Hawiflex® polyurethane. This also means that the high purity requirements in glass processing can be met. With our coatings, you can reduce residues in the glass and optimise your production process. A professional coating with polyurethane also reduces the noise level by up to 50 %. An important factor in increasing the sustainability of your business.

Hawiflex® – the original in PU wear protection

As an experienced company from Germany, our name Hawiflex by Contex stands for quality in the production of plastics. Thanks to its high abrasion resistance, our customised wear protection measures enable virtually residue-free processing of the raw material glass. We meet the biggest challenges in glass production and glass recycling – high abrasion – innovatively and focus on solutions to give our customers advantages and a head start within their industry at every stage of glass production and processing.

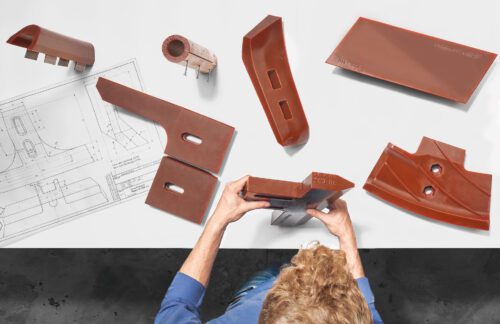

Hawiflex® PU coating

Your advantages at a glance:

- Free of metal residues

- High load-bearing capacity

- Impact and scratch resistant

- Cut and tear resistant

- Reduced noise level by up to 50

- Reduced downtimes

- Improved production costs

- Flexible options for retrofitting systems

- Highest quality standard

- Manufactured in Germany

Mixing blade

- Special formulation resistant against high temperatures

- Used in mixing process with raw materials for the glass production

Shard card

- Excellent cutting resistance

- Ideal for applications in the glass recycling industry

Hopper lining

- Single-part cone

- Simple installation

- No infiltration

- Easy to fix

- Excellent gliding properties

- Extremly long service life

Impact plate

- Standard plate

Transfer point for broken glass

- Spray coated

Vibrating chute

- Reduced adhesion

- Extended service life