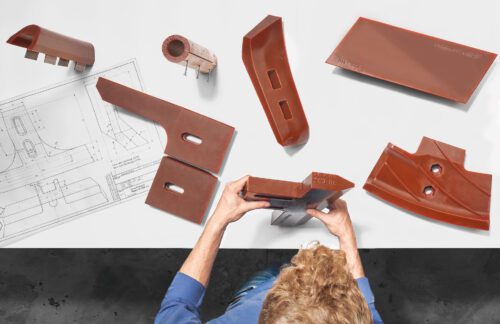

Hawiflex® polyurethane inliner

Wear protection and easy hopper cleaning

Cleaning concrete mixer drums is absolutely necessary to avoid increasing a vehicle‘s weight due to hardened residual concrete. It ensures that a ready-mix truck‘s maximum loading capacity is available and that the vehicle can be operated cost-effectively.

Unwanted residual concrete build-up is removed by a well-known, old-fashioned procedure – “cleaning by hammer”. Once a year, as a general rule, an employee gets into the mixer drum for a couple of hours, or up to five days, and removes the hardened residual concrete with a hammer and chisel. This type of work is almost unimaginable in terms of occupational safety – “working in an enclosed space” – and in view of the stress placed on the employee as regards dust and noise emissions. Cutting-edge, robot-controlled concepts for removing residual concrete from a mixer drum are now being employed for this work. A lance is introduced into the mixer drum and the cleaning process carried through in a short time using a high-pressure water jet. When utilised regularly, this procedure provides preventative protection against new caking. The cleaning lance has to be introduced horizontally through the infeed funnel. This is an almost impossible task, since any opening in the funnel would render it non-functional.

It is at this point that wear-resistant Hawiflex® polyurethane funnel linings – inliners –, which have been registered for a patent, can supply an innovative solution. An approximately 20 x 30 cm opening is made in the metal of the concrete infeed funnel. This allows the cleaning lance to be inserted. The funnel lining can then be put back into the concrete infeed funnel manually after the cleaning process. The funnel inliner made from Hawiflex® polyurethane closes off the opening for cleaning in the metal body; the ready-mix truck is now ready to be loaded again. This solution from Contex offers another important feature as regards protection against wear. Metal sheets to protect against wear are quite often inserted into infeed funnels to prolong their service life. The vehicle has to be taken out of service for this purpose. If an inliner made from Hawiflex® polyurethane is employed, then all protective functions are assumed by this inliner. The inliner can be replaced with ease in a few seconds should there be wear. Two to four working hours are usually reckoned for removing and reaffixing new metal protection sheets. This means that an inliner made from Hawiflex® polyurethane possesses a considerable advantage. Its service life expectancy is approximately three times greater than the wear protection solution with metal sheets.